One, the range of work and various parameters (mm)

Two, the main technical indexes and characteristics

1, the cleaning of the filter precision:

A, rough cleaning filtering accuracy ≤ 10um

B, the spray cleaning filtering accuracy ≤ 1um

C, ultrasonic cleaning filtering accuracy ≤ 0.22um

2, measurement error:

A, inner and outer diameter measuring (point) repeat accuracy ≤ 0.8um

B, inner and outer ring assembly of high measurement precision ≤ 5.0um

3, full automatic roller and cage assembly equipment, roller, roller to detect leakage flip 100%, imaging system or high precision detection system of on-line detection

And after the assembly of high detection

4, nondestructive hardness testing repeatability precision

5, inside diameter, raceway measurements with automatic standard proofreading function, in the proofing cycle prefabricated within the set, testing machine can be the standard

To a testing station to proofread, proofread results can be measured automatically reply system calibration value.

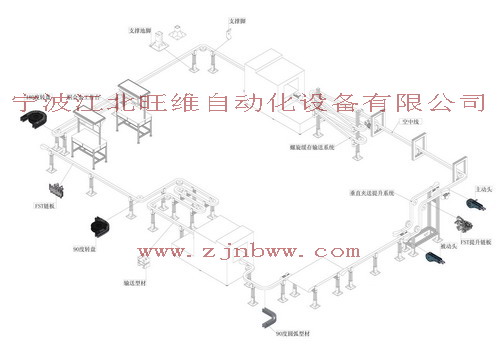

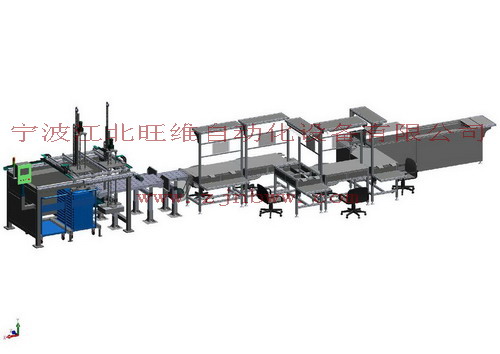

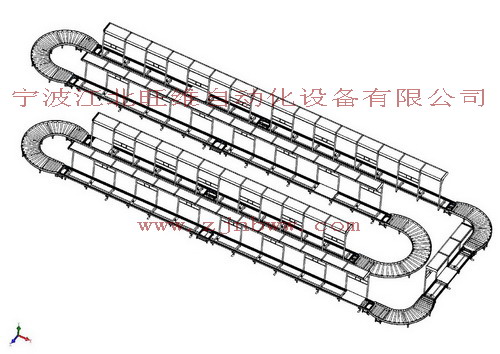

Three, equipment composition

1, the inner ring: (feeding machine, laser marking mechanism (purchase), materials (optional)), component assembly and riveting, demagnetization mechanism, cleaning machine

The → drying mechanism, vibration testing, assembly of high detection, cleaning mechanism, the drying mechanism, hole size / measurement mechanism (optional), leakage detection

Measurement, spray antirust oil mechanism, feeding machine

2, the outer ring: feeding machine, laser marking mechanism (optional), feeding, demagnetization mechanism, cleaning mechanism, drying mechanism, outer diameter / assembly of high measuring machine

The (optional)